Circular saw operation

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Hand-held circular saws are generally simply called 'power saws'.

For an underlay installation, you may use a power saw to cut wood-based underlays to size, cross-cut timber or re-trim existing wooden subfloors.

It is possible to cut fibre cement sheets with a circular saw, but you should use an approved dust extraction system attached to the saw housing and a blade made specifically for fibre cement sheets.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

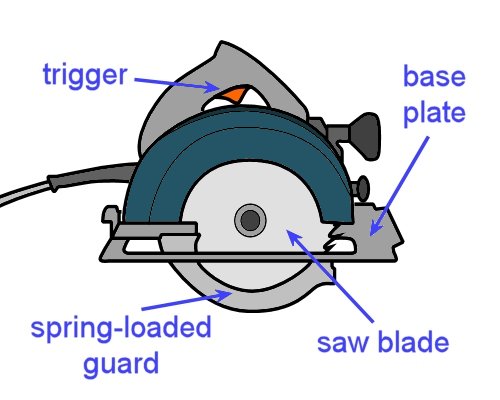

Unlike an electric planer, you don't need to wait until the saw has stopped turning before you put it down, because the spring-loaded guard will flick back into place when you remove the saw from the work.

But this means you have an additional safety check to carry out - always make sure the guard is moving freely and springing back to its correct position before connecting the saw to the power supply.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Basic operating procedure

- Secure the material to be cut so it can't move. Draw a line to mark the cut.

- Check the saw blade for damaged or blunt teeth. Check that the spring-loaded guard is working properly. Adjust the saw to the required depth and angle.

- Plug the saw into the power supply. Make sure the power lead is clear, and position your feet so you're in a comfortable balanced position.

- Rest the front of the base plate on the material to be cut and check that it's sitting flat on the surface.

- Start the saw and allow it to reach full speed before commencing the cut. Push the saw smoothly forward with an even motion. Make sure the saw stays straight - don't twist the blade in the cut.

- Keep the saw straight as you leave the cut and don't release the trigger until the blade is clear of the material.