Power sources

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Most of the hand-held tools used to install floor coverings are powered by old-fashioned muscle power.

However, hard underlay panels are often cut to size and fixed in position using tools that run on mains electricity, battery or compressed air.

You need to be very careful when using power tools not to expose yourself or others to danger, because the power sources can cause injuries and even death if they're not treated with great respect.

Below are the main safety considerations you need to keep in mind when using power tools, and some information on how the different power sources work.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Mains electricity

Mains power - often called 240 volt power - is used everywhere, but that doesn't mean you should take its safety for granted.

Every year people are hospitalised as a result of electric shock, and occasionally the shocks prove fatal.

Electrical faults are also responsible for many fires, because the sparks from short circuits or the heat from overloaded wires can ignite flammable substances or materials.

The first rule when using power tools is to make sure the electrical cable is in good condition.

Check that the insulation is sound and there are no exposed wires at the plug end or the other end where it enters the tool.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

The second rule is to avoid using electrical tools in wet conditions. If it has been raining, or you're in a wet area, only use the tool if:

- your hands are dry

- the tool is completely dry

- you are wearing rubber soled boots and standing on a dry surface

- electrical leads and connections are clear of damp ground.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

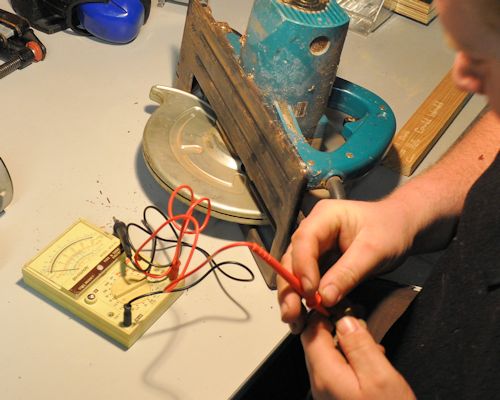

Testing and tagging

It is a WorkSafe requirement that all power tools used at work are tested and tagged every three months by an authorised person.

The test is designed to ensure that the tools are safe and not likely to cause a fire or electric shock.

Once a piece of equipment has been tested and passed, the authorised person attaches a tag to it, stating their name or company they work for and the test date.

If you pick up a power tool and find that the tag is out of date, make sure you take it straight to the person responsible for getting it tested.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Here's some tips on using extension leads safely:

- Fully unwind a long lead before you use it. Leads that are left coiled up can generate a lot of heat when there's a current passing through them.

- Check the plugs at each end to make sure that the wires aren't starting to pull out. If the plugs or lead are not in good condition, tag it and take it straight back to your supervisor for repairs.

- Never pull a plug out of a socket by tugging on the lead. Always hold the body of the plug when you remove it.

- Keep leads clear of wet patches on the ground or floor. This especially applies to any joins in leads.

- As a rule of thumb, use leads rated at a minimum of 10 amps for power tools, and 15 amps or more for large machines.

- Try to keep the lead as short as possible for the job you're doing. The longer a lead is, the higher the voltage drop will be from one end to the other, so the higher its amp rating will need to be.

- Don't drape leads across walkways, access-ways or vehicle paths. If there is no alternative to running a lead across a thoroughfare, make sure the lead is very obvious, and either protect it from vehicle and pedestrian traffic or put it overhead.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

Compressed air

Tools driven by compressed air are called pneumatic tools.

They tend to be more efficient and lighter than equivalent tools powered by mains electricity, because they do away with the need for an electric motor inside the tool.

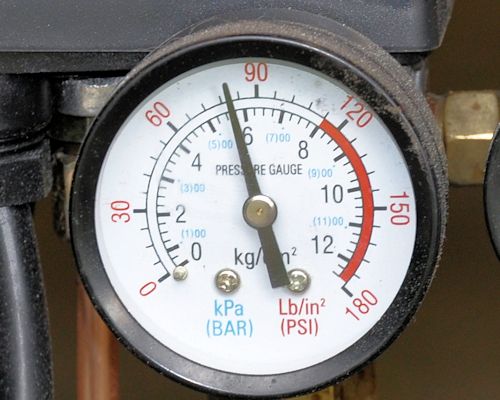

The compressor itself has a pump which compresses air from the atmosphere.

A receiver, or storage tank, holds the compressed air, and an automatic pressure regulator keeps it at the correct pressure by switching the pump on and off.

If the pressure gets too high, air is released through a safety valve.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

It's a good rule to use the minimum pressure required for the tool to operate properly.

This will help the compressor to use less power, and there'll be less wear on the tool.

If you're using a nail or staple gun, it will also reduce the chance of the fasteners countersinking too far and damaging the surface of the material you're firing into.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

Although compressed air is safer than electricity in some respects, it has other hazards that can be just as dangerous. Here's some safety guidelines you should follow:

- Always wear safety glasses when using compressed air. This includes blowing out tools or cleaning down work areas with an air hose. The air will cause particles to fly in all directions at high speed.

- Never point a stream of compressed air directly at anyone's body, particularly bare skin. This includes not cleaning sawdust off yourself with an airgun.

- Make sure you secure the loose end of an air hose before turning on the air, to stop it from whipping around when it takes up pressure.

Audio for slide 10 (mp3 |6|KB)

Audio for slide 10 (mp3 |6|KB)

Rechargeable batteries

As rechargeable batteries continue to improve in performance and power output, an increasing variety of 'cordless' tools are coming onto the market, including jigsaws, circular saws, planers, and even chainsaws.

In general, battery-powered tools are less powerful than the same-sized tool that runs on mains electricity.

However, for on-site work their convenience often outweighs the reduction in power.

Always remember to pack the battery charger when you take cordless tools to the jobsite. It's also a good idea to take two batteries, so you can leave one on 'charge' while the other is in the tool.

Learning activity

Audio 11 (mp3 |6|KB)Choose a hand-held power tool you're familiar with that is available in both cordless and main power versions. Answer the following questions.

- What type of tool is it?

- What are two advantages of the cordless version (over the 240-volt version) when you're using the tool on-site?

- What are two disadvantages of the cordless version when you're using it on-site?