Hardboard

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Hardboard is made from wood fibres compressed into a sheet in a high temperature press.

In principle, the bonding is achieved entirely through the 'felting' process of the fibres and the natural glue, or lignin, already present in the wood.

However, other chemicals can be added to improve the board's strength and resistance to moisture, fire, insect attack and decay.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

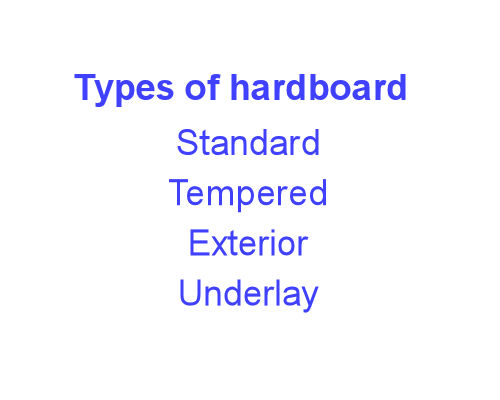

The various hardboard products often look much the same, even though they're made for different purposes.

Here is a summary of the main types of products, just so you don't get confused between them if you're presented with a choice.

- Standard hardboard is used for wall linings, door skins, cabinet backs, drawer bases, and other interior purposes.

- Tempered hardboard is treated to give it more strength and better resistance to moisture, so it can be used as a lining board where moisture may be present.

- Exterior hardboard is treated to make it resistant to moisture and weathering, so it can be used for cladding and other outside applications.

- Underlay hardboard is treated to improve its moisture resistance, and is manufactured specifically for use under floor coverings. The typical sheet size for hardboard underlay is 1220 x 915 mm (4 ft x 3 ft). The thickness is 5.5 mm.

Go to Fibre cement

Industry Network Training and Assessment Resourses

© 2023 Workspace Training