Carpet tile construction

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

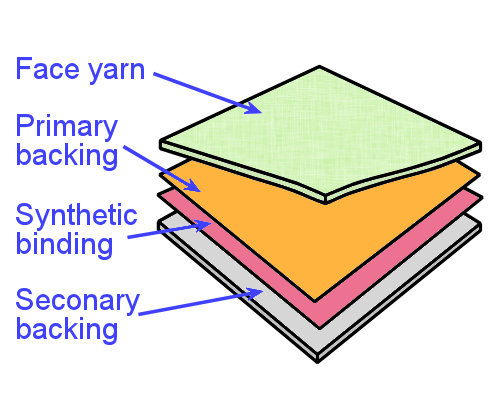

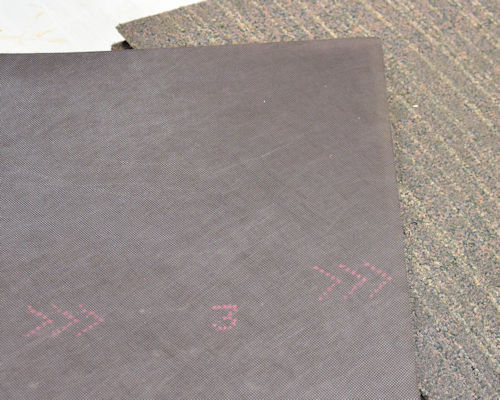

The yarn is held in place by the primary backing, and secured with an adhesive binding.

The materials used in primary backings include glass fleece, polypropylene or polyester.

A secondary backing is used to give the carpet tile extra strength and dimensional stability. In cushion-backed tiles, it also provides the padding.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Secondary backing materials include bitumen, PVC (polyvinyl chloride), polypropylene and glass fleece. Cushion-backed carpets generally have a polyurethane, PET (polyethylene terephthalate) or SBR (styrene-butadiene rubber) foam backing.

Recycled products are increasingly being used in the manufacturing process, and it is now common for at least 50% of the content to be derived from recycled materials.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Needle punched carpet

Needle punched carpet tiles tend to be used more in temporary installations, such as short-term set-ups in exhibition halls. In general, they are not suitable for the contract market.

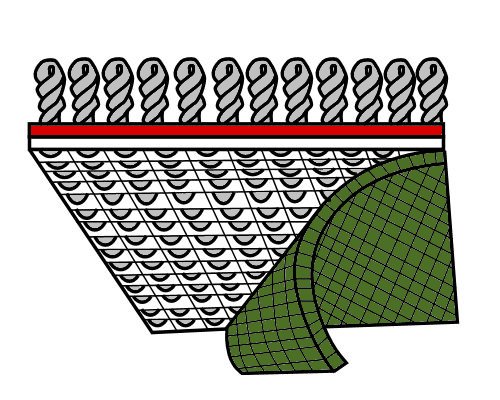

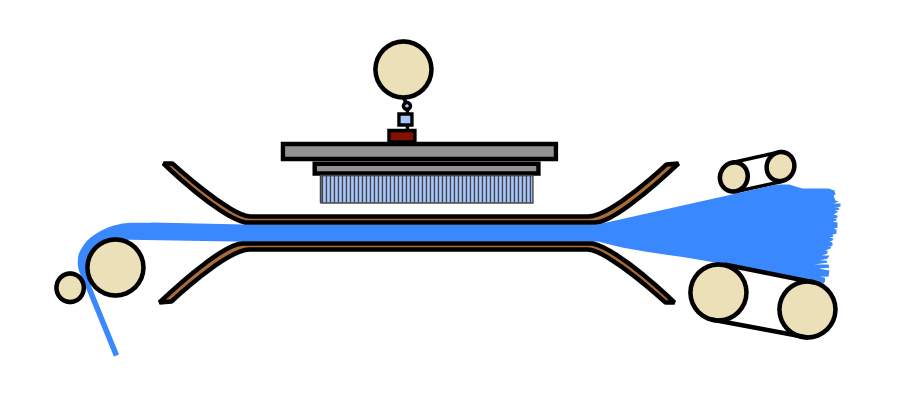

The manufacture of needle punched carpet begins with the fibres being laid into a web.

The web is fed into the needle loom by feed rollers and passed between two plates.

As the web passes through the loom, the needle plate moves up and down, allowing the needles to penetrate the web through corresponding holes in the plates. This process entangles the fibres and forms the carpet tile surface.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Fusion bonded carpet

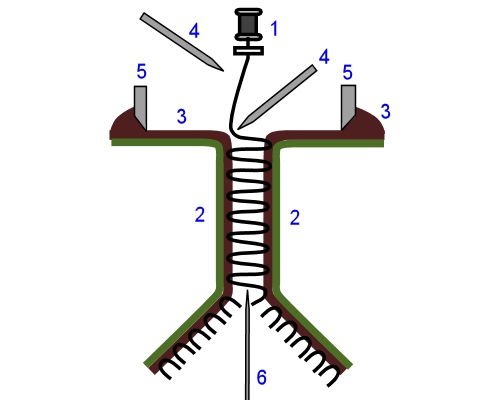

The main difference between bonded carpet and tufted carpet is that fusion bonding relies entirely on the adhesive layer to hold the pile material in position - the yarn does not penetrate the backing fabric at all.

Bonded carpet is made by lapping the pile yarn (shown as 1 in the drawing at right) backwards and forwards between two backing materials (2) coated with adhesive (3).

The yarn is implanted into the adhesive with pleating blades (4), and the adhesive thickness is controlled by a glue scraper (5).

Once the adhesive has set, the 'sandwich' is then split down the centre with a knife (6) to form two separate carpets.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

Antimicrobial treatments

Carpet tiles used in hospitals, nursing homes and other health care settings generally have an antimicrobial treatment incorporated into the yarns, precoat or backing system.

The chemical treatment helps to protect the carpet against the spread of moulds, mildew, bacteria and odour-causing microorganisms, especially where the carpet edges meet.

Learning activity

Audio 8 (mp3 |6|KB)Choose one carpet tile product you are familiar with and do some research on its properties and the materials used in its manufacture.

Provide the following details about the product:

- brand name and manufacturer

- pile texture, and type of fibre used in the yarn

- materials used in the primary backing and secondary backing

- any other features, such as whether it has an antimicrobial treatment or particular properties that make it suitable for certain types of installations.