Carpet construction

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

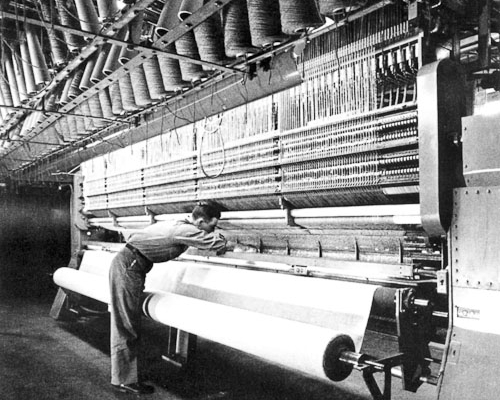

By the 1920s, factory machines began to take over the process, and the first broadloom tufted carpet machine (12 foot wide, or 3660 mm) was built in the 1950s.

These days, tufted carpets have come to dominate the market in domestic installations.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

This manufacturing method is most commonly used to make carpet tiles, but it can also be used to produce rolls.

Let's look briefly at the techniques used to make these two types of carpet, and the effects they have on the way the carpet looks and performs.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

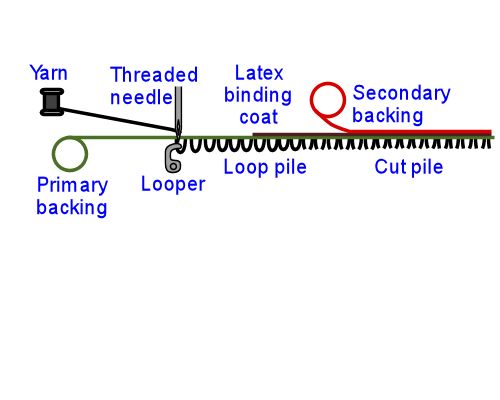

Tufted carpet

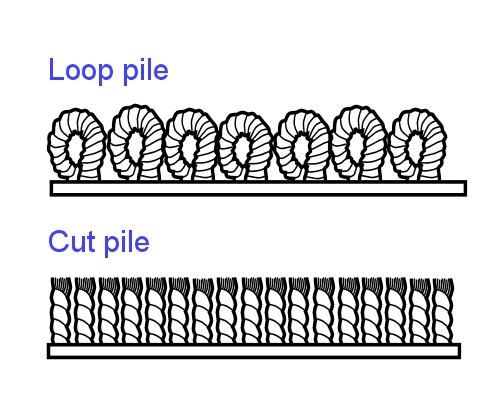

'Tufting' refers to the process of inserting tufts of yarn into a backing cloth with a needle.

The tufting loom has hundreds of needles that work like a sewing machine.

After the tufts have been anchored into the primary backing with a latex adhesive, a secondary backing is added to give the carpet better dimensional stability.

This extra stability helps when the carpet is stretched into place during installation.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

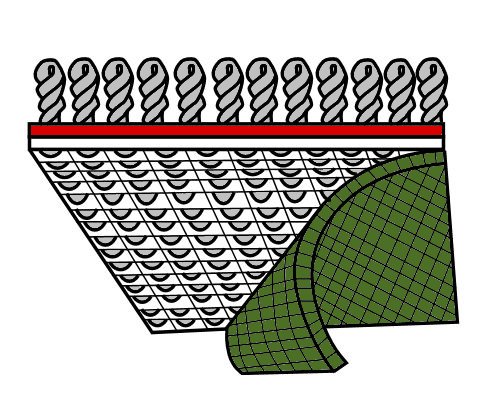

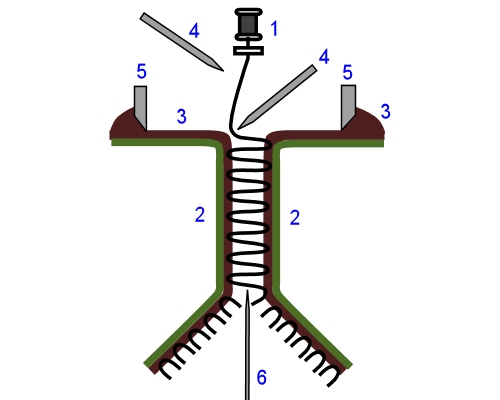

The diagram at right shows the main parts of a tufting loom.

Here are some more details on the terms used in the diagram:

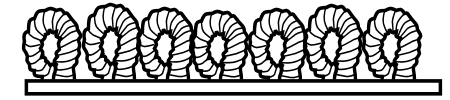

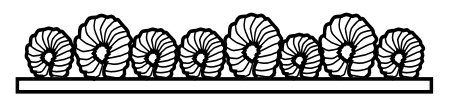

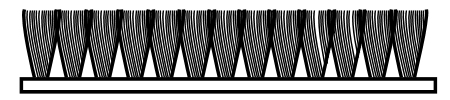

Pile: formed from the yarn, which can be either coloured before manufacture, or dyed or printed after manufacture

Primary backing: the cloth that holds the tufts in place until the secondary backing is applied

Latex Adhesive: the adhesive that seals the fibres in position and bonds the secondary backing

Secondary backing: an extra backing layer that stabilises the material and helps it to stretch but stay in shape.

| 1. Level loop |  |

| 2. Multi-level loop |  |

| 3. Berber |  |

| 4. Velvet/plush |  |

| 5. Saxony |  |

| 6. Frieze |  |

| 7. Tip sheared |  |

| 8. Random sheared |  |

| 9. Shag |  |

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Fusion bonded carpet

The main difference between bonded carpet and tufted carpet is that fusion bonding relies entirely on the adhesive layer to hold the pile material in position - the yarn does not penetrate the backing fabric at all.

Bonded carpet is made by lapping the pile yarn (shown as 1 in the drawing at right) backwards and forwards between two backing materials (2) coated with adhesive (3).

The yarn is implanted into the adhesive with pleating blades (4), and the adhesive thickness is controlled by a glue scraper (5).

Once the adhesive has set, the 'sandwich' is then split down the centre with a knife (6) to form two separate carpets.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

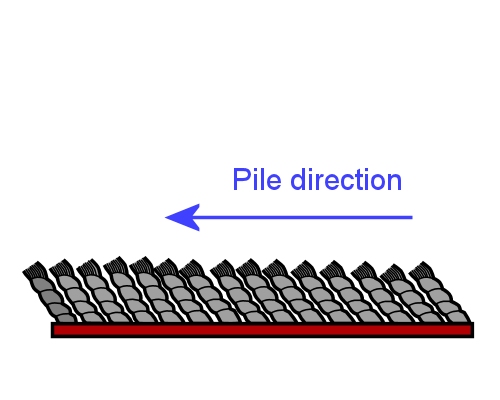

Pile direction

The pile of a carpet tends to lay in a particular direction.

If it's laying towards you, it will look darker because you're looking 'into' the pile.

If it lays away from you, it will look lighter because you're looking 'over' the pile.

Whenever you put two pieces of carpet side by side, you need to make sure that the pile direction is the same on both pieces.

Manufacturers generally put a coloured thread on the backing on one side to indicate the pile direction.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

Backing materials

Jute is the traditional fibre used in tufted carpet backing materials.

It has good dimensional stability and is able to stretch.

However, if it gets wet it will shrink, and sometimes leave a brown or yellow stain on the pile surface.

It is also an imported material and not always reliable in terms of availability.

These days, jute is not commonly used for primary backing, but is still the preferred material for secondary backing.

Audio for slide 10 (mp3 |6|KB)

Audio for slide 10 (mp3 |6|KB)

They are economical, waterproof and stretchable.

However, they are heat-sensitive, which can cause problems with some manufacturing techniques, as well as installations that involve hot-melt seams.

They also tend to fray when they're being cut or seamed during installation.

Fusion bonded carpets use layered vinyl or plastic backing materials, with a fiberglass scrim for dimensional stability.

Audio for slide 11 (mp3 |6|KB)

Audio for slide 11 (mp3 |6|KB)

Carpet fibre

There are several types of fibre used in carpet.

Each has its advantages and disadvantages as a raw material, but when the varying characteristics are taken into account during the manufacturing and installation processes, they all perform well on the floor.

In Australia, the three most commonly used fibres are:

- nylon

- polypropylene (also called 'olefin')

- wool.

Some carpets are made of fibre blends, such as 80% wool and 20% nylon.

Learning activity

Audio 12 (mp3 |6|KB)Do your own research on tufted and bonded carpets and come up with one brand name and manufacturer for each of the following three types of fibres: nylon, polypropylene and wool. Also identify one fibre blend.

For each one, provide the following details: pile texture, backing materials, and construction method (i.e. tufted or fusion bonded).