Electricity

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Note that heavy industrial machines generally run on 415 volt power, also called 'three-phase' power.

However, they use a different type of power plug and socket and are not produced in the hand-held range of power tools.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Mains electricity

Some people refer to mains electricity as '240 volt power', because that's the voltage that comes out of a standard power point.

Standard power points are designed to take two-pin or three-pin plugs. One pin connects to the active or live wire. The opposing pin connects to the neutral wire, which completes the circuit.

The bottom pin has no role in delivering electricity, but connects the tool to the earth wire as a safety mechanism, in case there is a malfunction or 'short circuit'.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

There are two main systems of insulation used in power tools:

- Single insulated tools use an earth wire which is connected to the metal casing of the tool at one end and the earth pin of the plug at the other end.

In the event of a fault that causes a short circuit, the current is able to flow straight to earth without giving the operator an electric shock.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

Rechargeable battery

As rechargeable batteries continue to improve in performance and power output, an increasing variety of 'cordless' tools are coming onto the market, including jigsaws, circular saws, planers, and even chainsaws.

However, by far the most common cordless power tool is the drill.

This is because most drills are smaller and consume less power than the other types of tools, so their rechargeable batteries are lightweight and relatively cheap.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

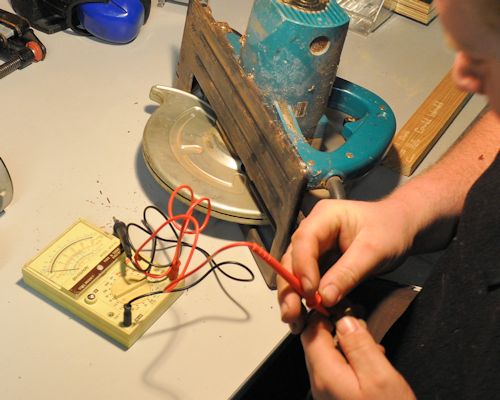

Safety with mains power

Mains power is used everywhere, but that doesn't mean you should take its safety for granted.

Every year people are hospitalised as a result of electric shock, and occasionally the shocks prove fatal.

Electrical faults are also responsible for many fires, because the sparks from short circuits or the heat from overloaded wires can ignite flammable substances or materials.

Audio for slide 10 (mp3 |6|KB)

Audio for slide 10 (mp3 |6|KB)

The second rule is to avoid using electrical tools in wet conditions. If it has been raining, or you're in a wet area, only use the tool if:

- your hands are dry

- the tool is completely dry

- you are wearing rubber soled boots and standing on a dry surface

- electrical leads and connections are clear of damp ground.

Audio for slide 12 (mp3 |6|KB)

Audio for slide 12 (mp3 |6|KB)

If you pick up a power tool and find that the tag is out of date, make sure you take it straight to the person responsible for getting it tested.

Audio for slide 13 (mp3 |6|KB)

Audio for slide 13 (mp3 |6|KB)

Setting up extension leads

If the power source is not close to the area you're working in, you may need to run an extension lead some distance.

Always make the effort to keep extension leads safe, because they can be a serious hazard to your own team as well as other workers on-site if you don't.

Click on the link below to see some tips on how to use extension leads safely.

Tips on using extension leads at jobsites

Learning activity

Audio 14 (mp3 |6|KB)Write up a list of the hand-held electric tools you regularly use, naming their brand and power source (mains power or battery).

Also state the size of the tool if you know it. Note that the size is generally expressed in terms of the attachment that does the actual work - such as blade diameter, cutter length or drill bit diameter.

Here are some examples of how the size might be described:

| Drill: | 10 mm (3/8 inch) | referring to the maximum diameter drill bit that can be put into the chuck |

| Circular saw: | 115 mm (4 1/2 inch) | the diameter of the blade |

| Electric planer: | 75 mm (3 inch) | the width of the cutters |